Packaging Redesign

Senior Thesis @ Western Michigan University

Overview

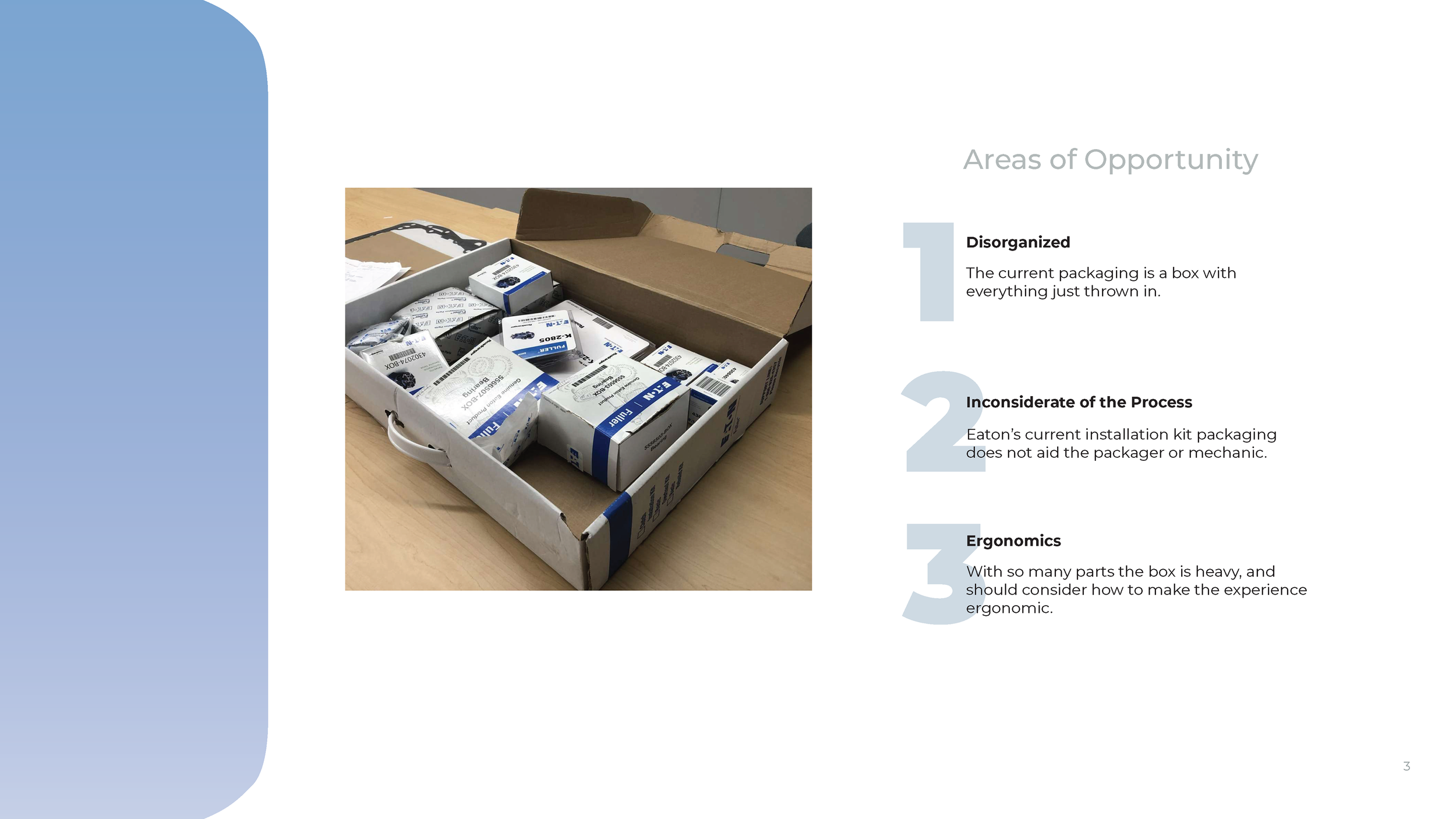

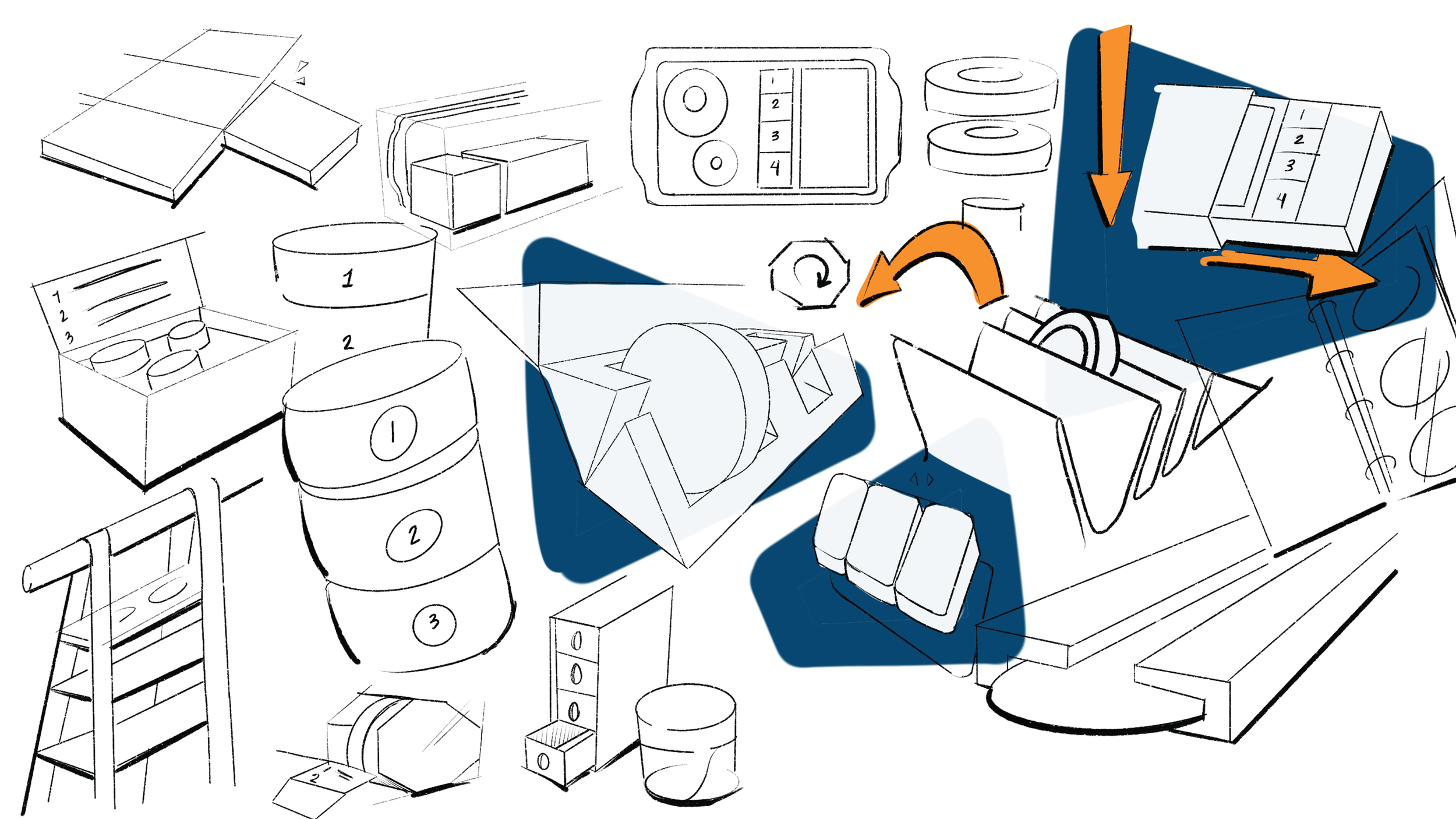

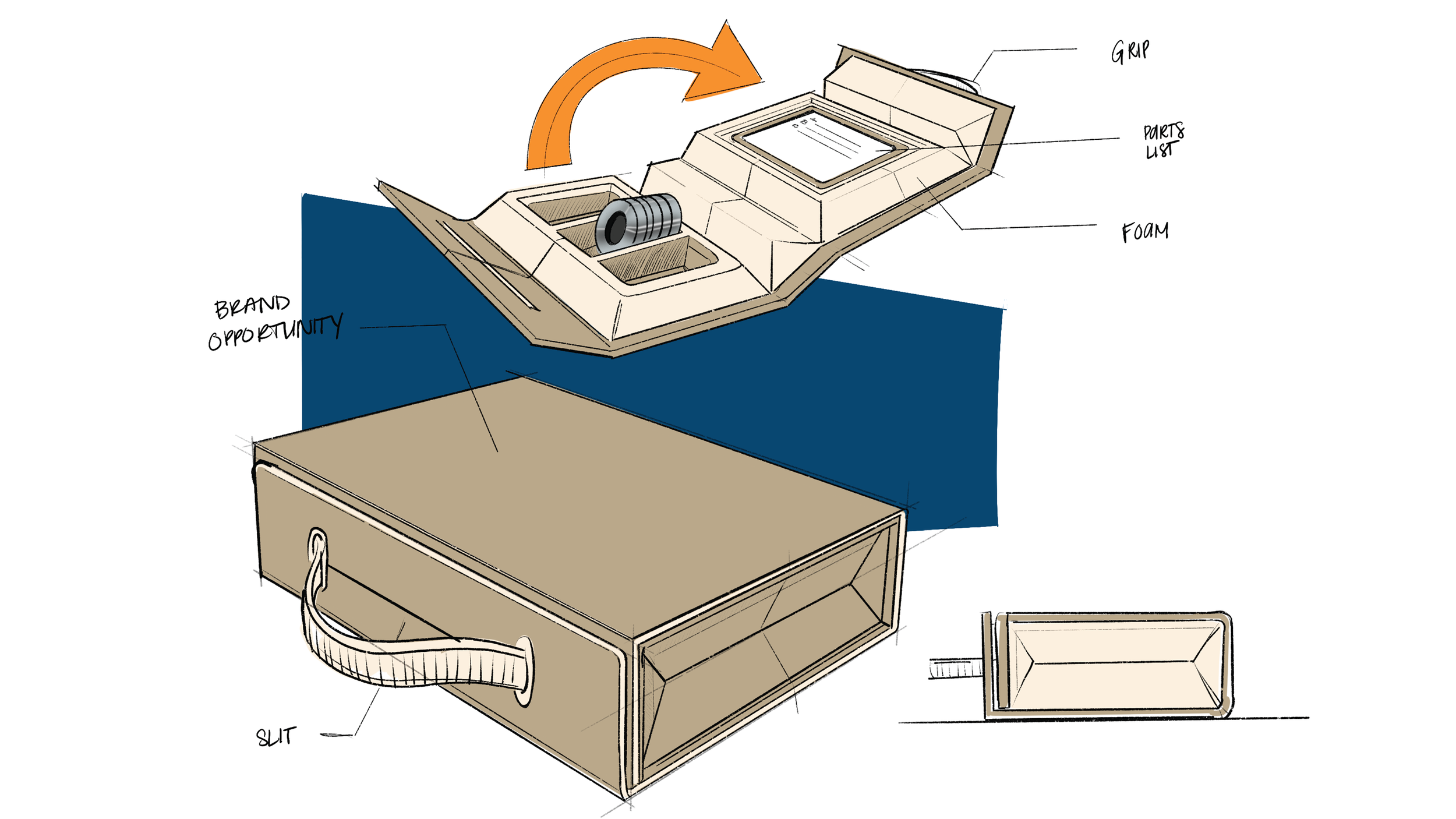

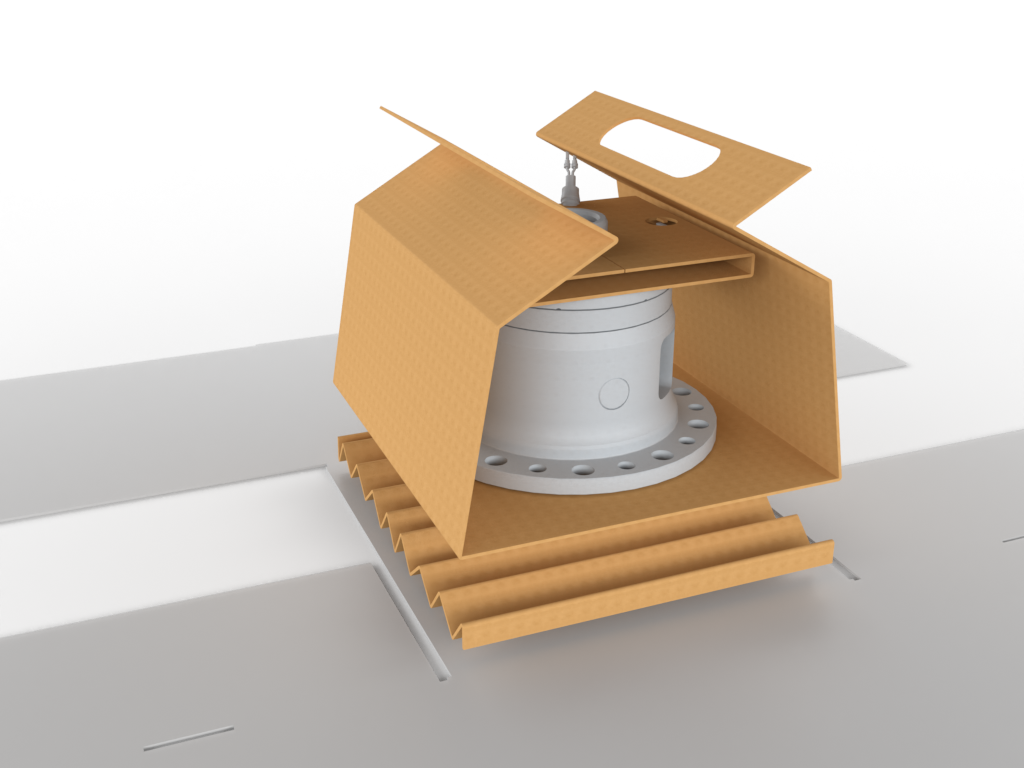

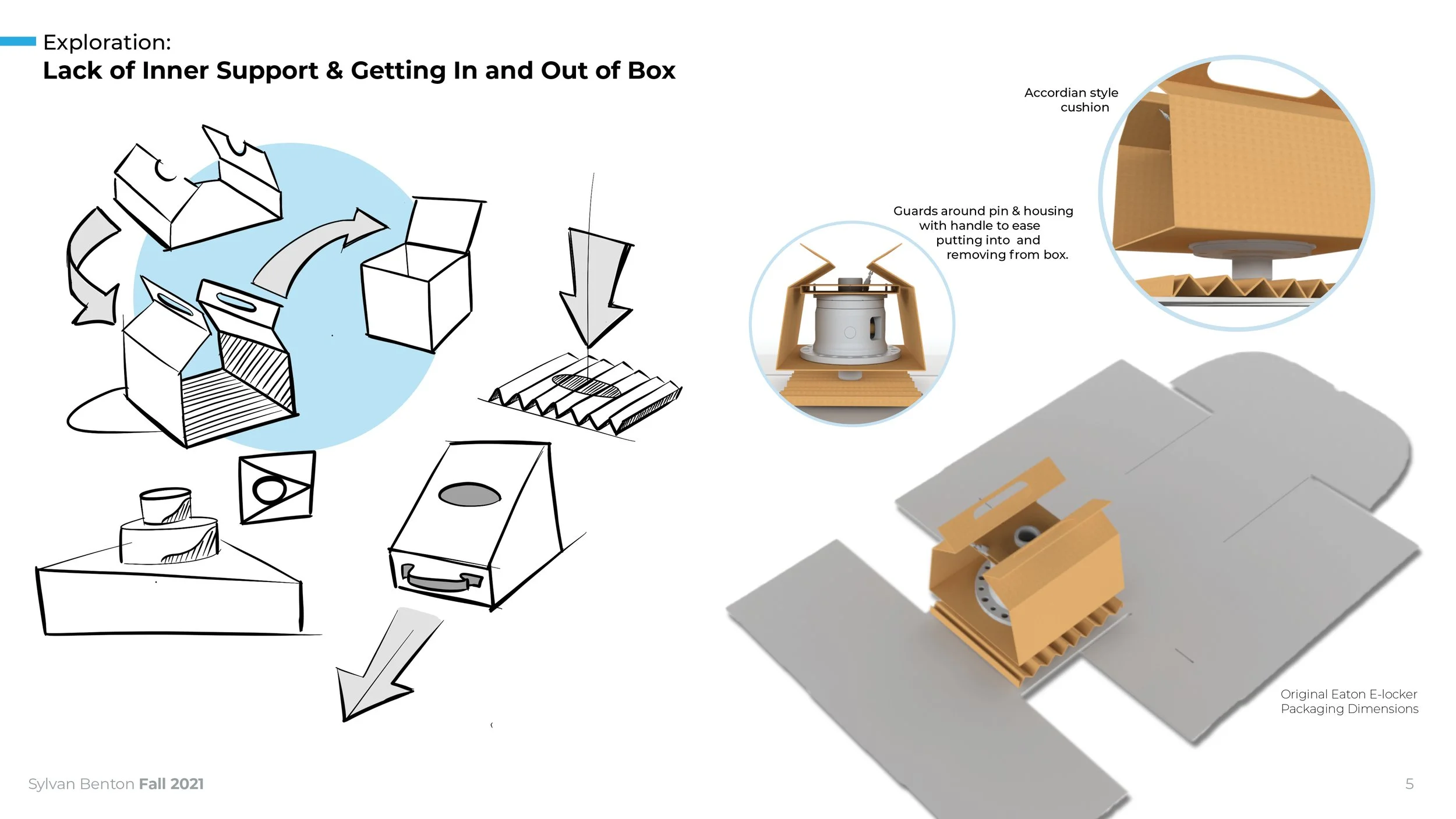

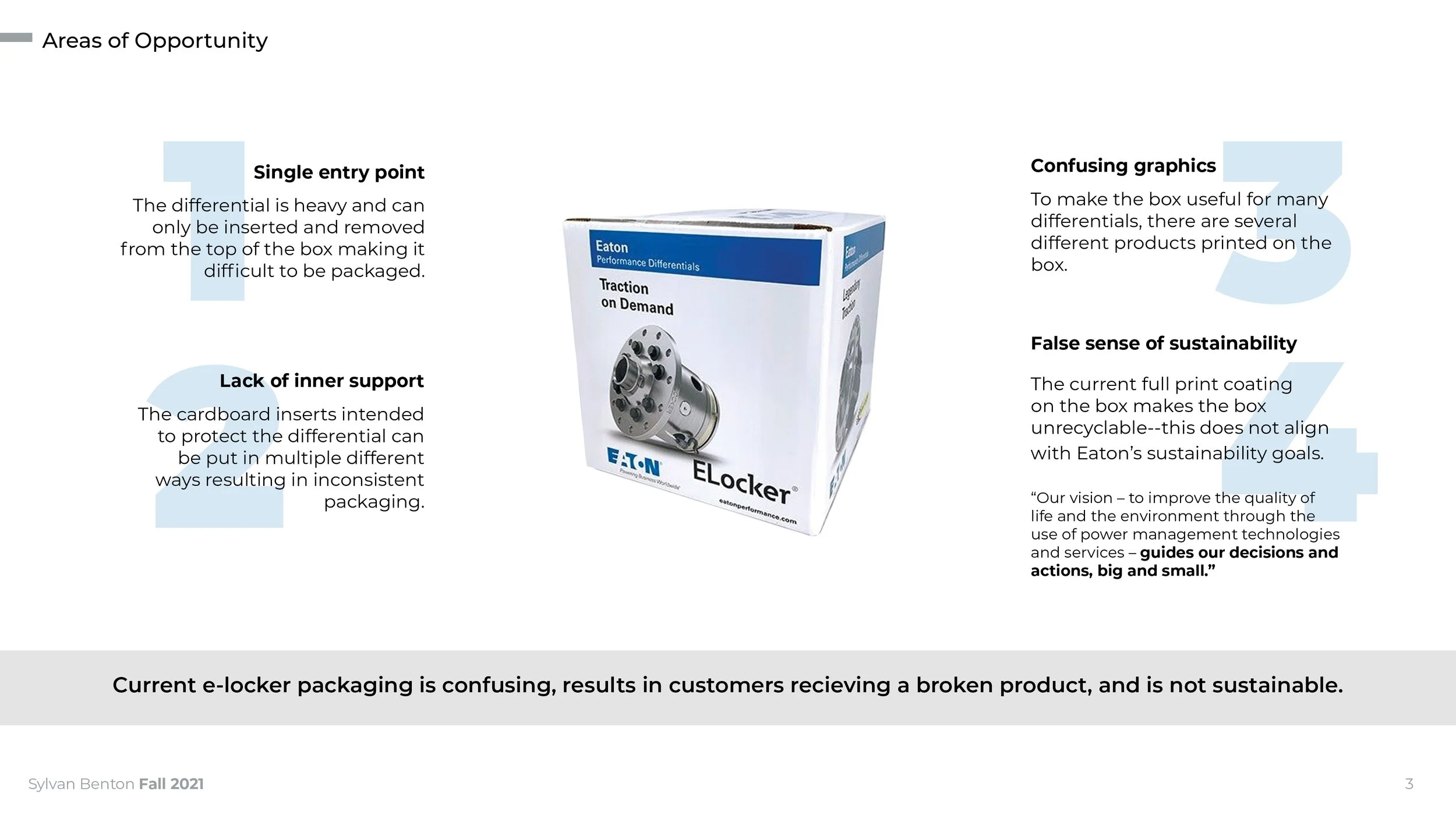

I reimagined installation kit packaging for Eaton, transforming a disorganized unboxing experience into an intuitive, process-oriented design that serves multiple stakeholders across the product lifecycle. By focusing on the human touchpoints—from assembly line workers to delivery drivers to mechanics—I created a solution that improves efficiency while enhancing the experience for everyone who interacts with the product.

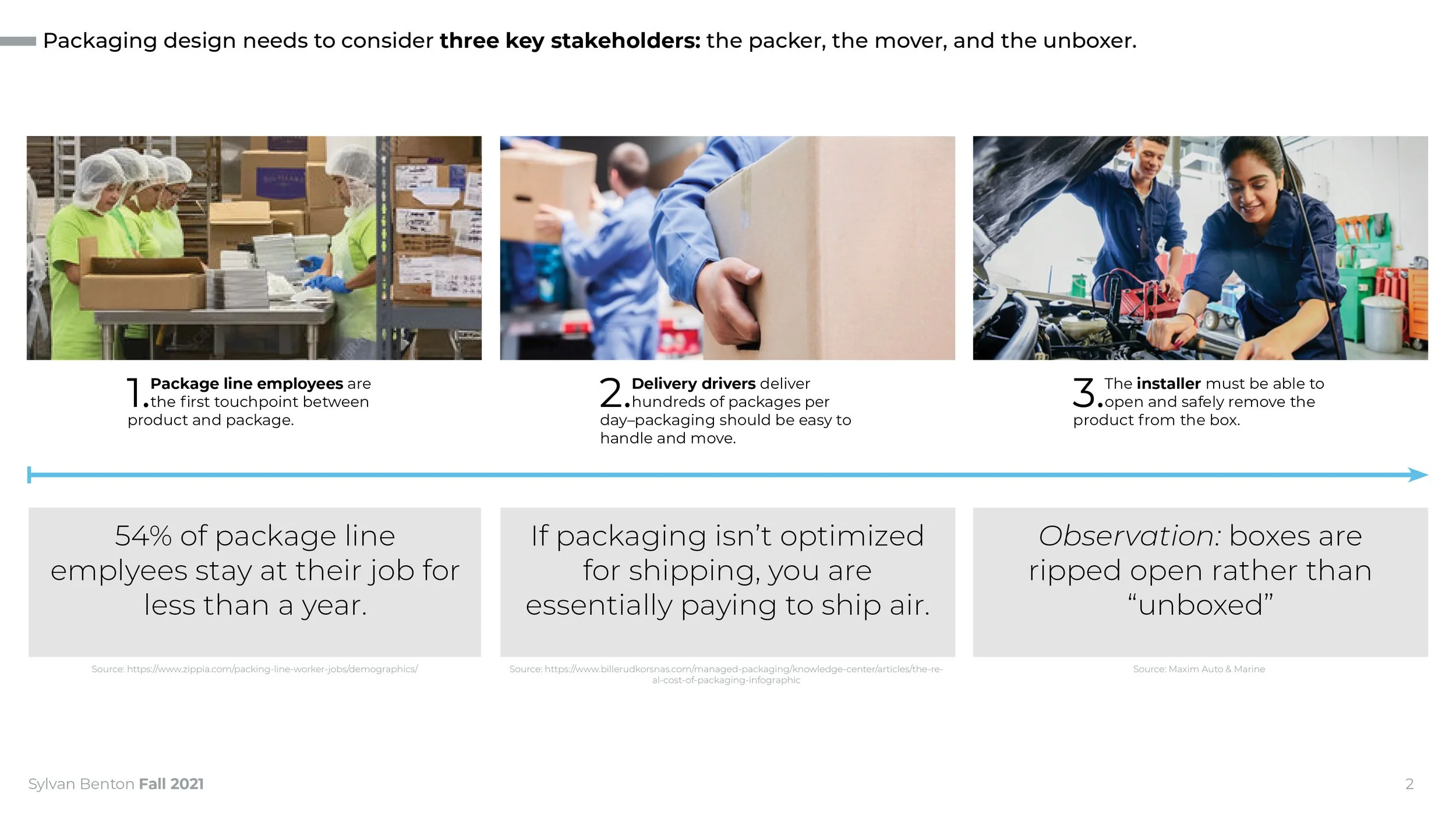

Goal

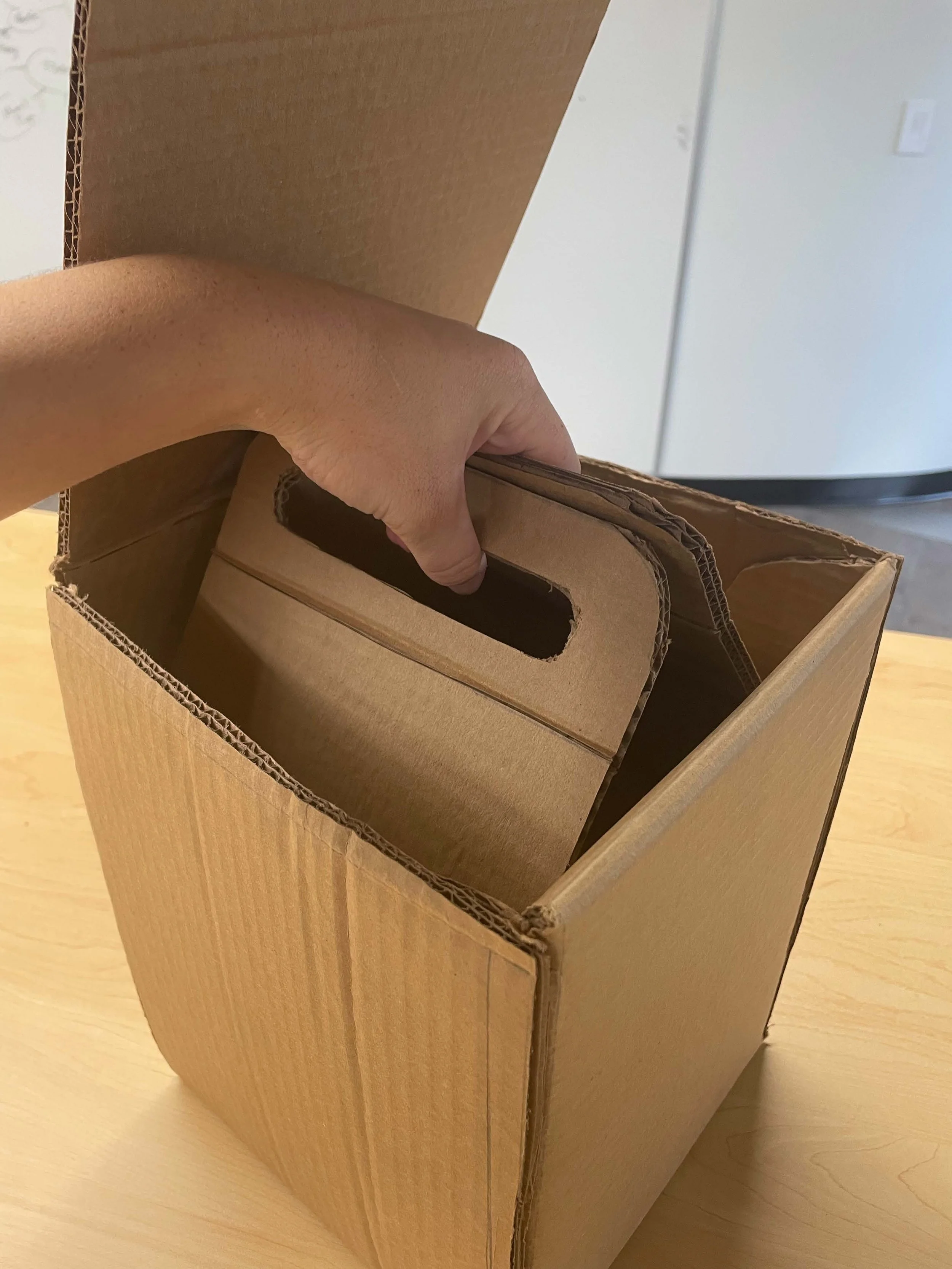

Design packaging that addresses three key stakeholder needs: improve the experience for package line employees (54% of whom stay less than a year), optimize shipping efficiency for delivery drivers, and create an intuitive unboxing experience for mechanics who typically rip open rather than carefully unbox installation kits.

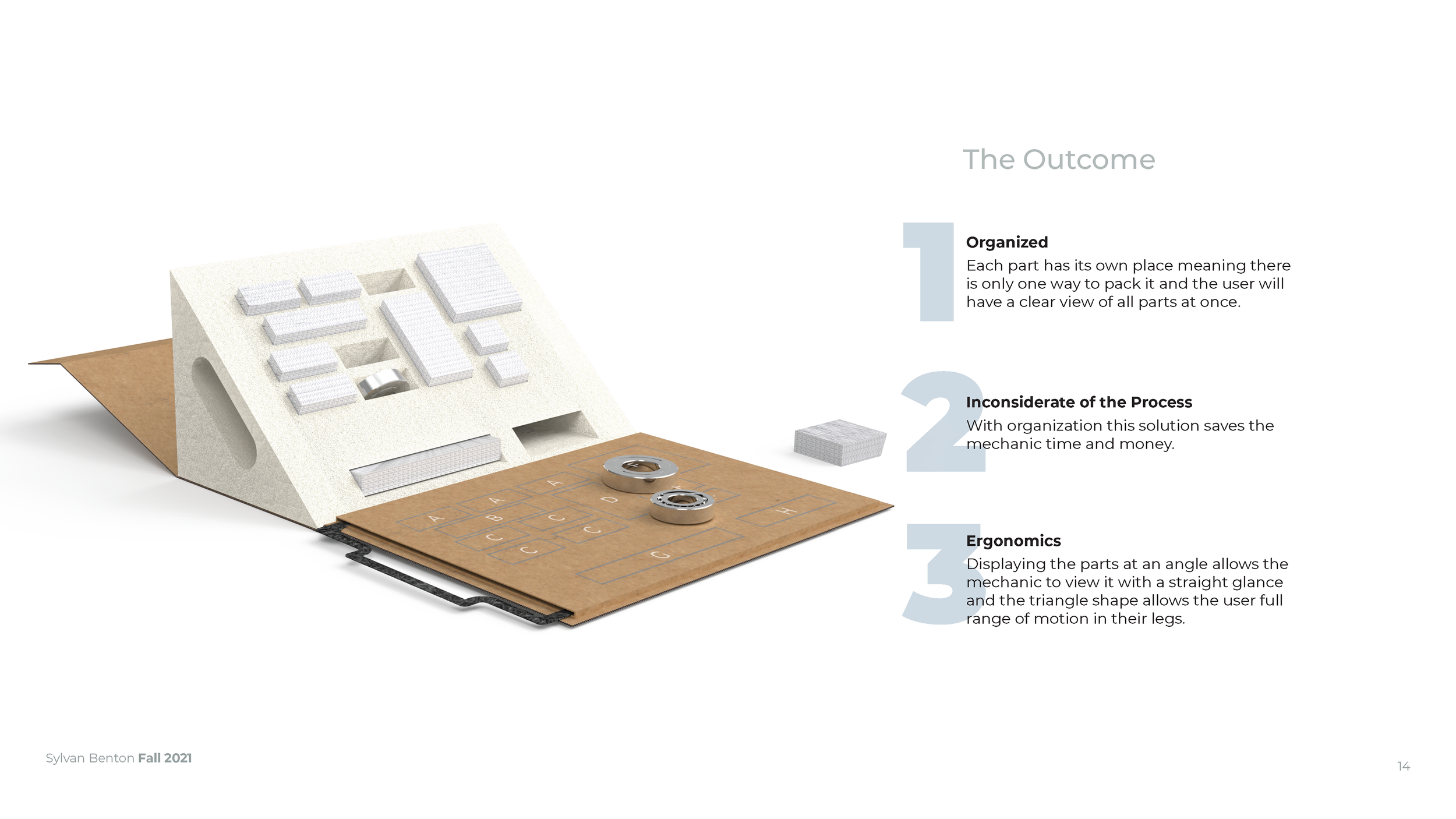

Outcome

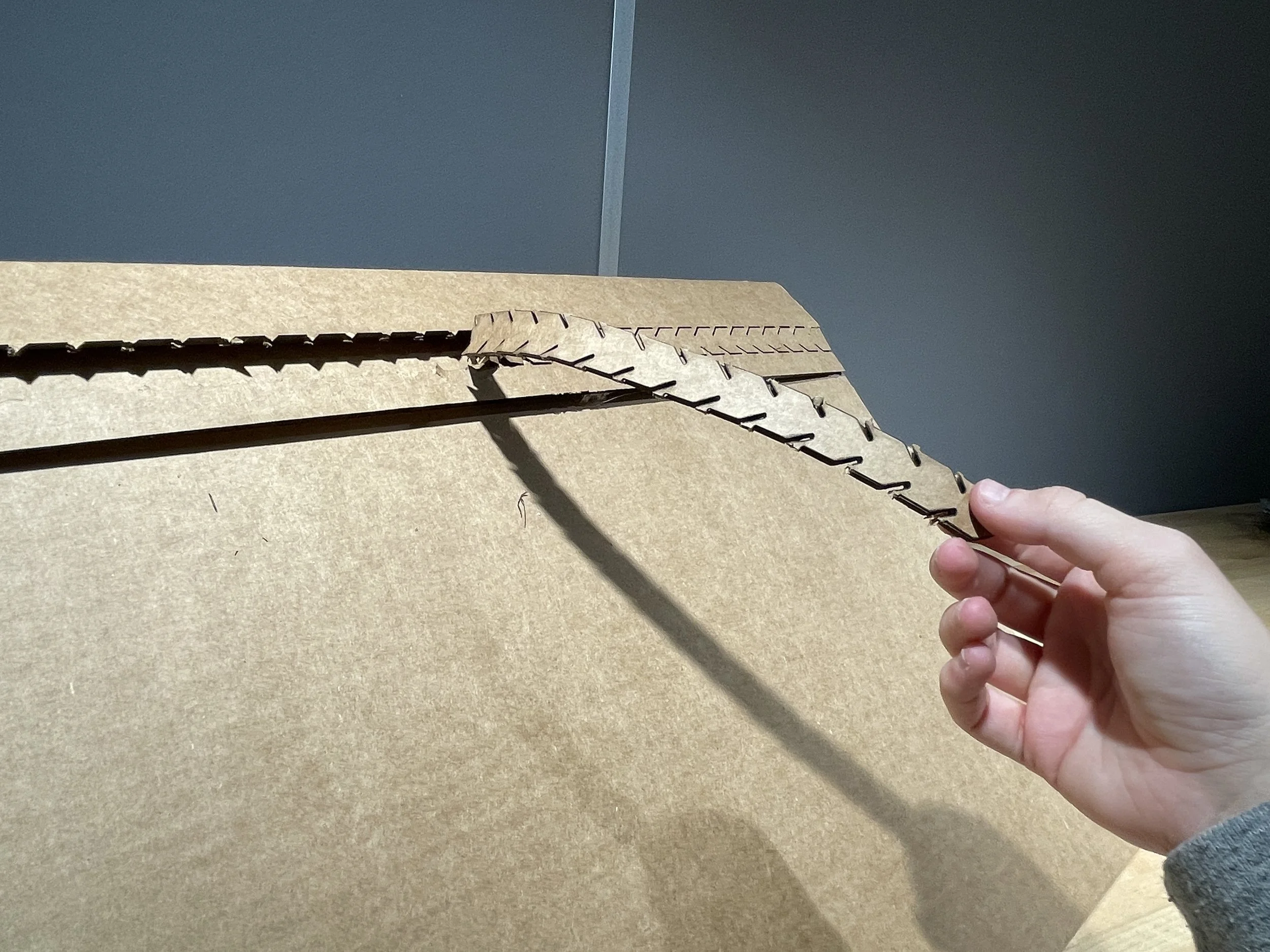

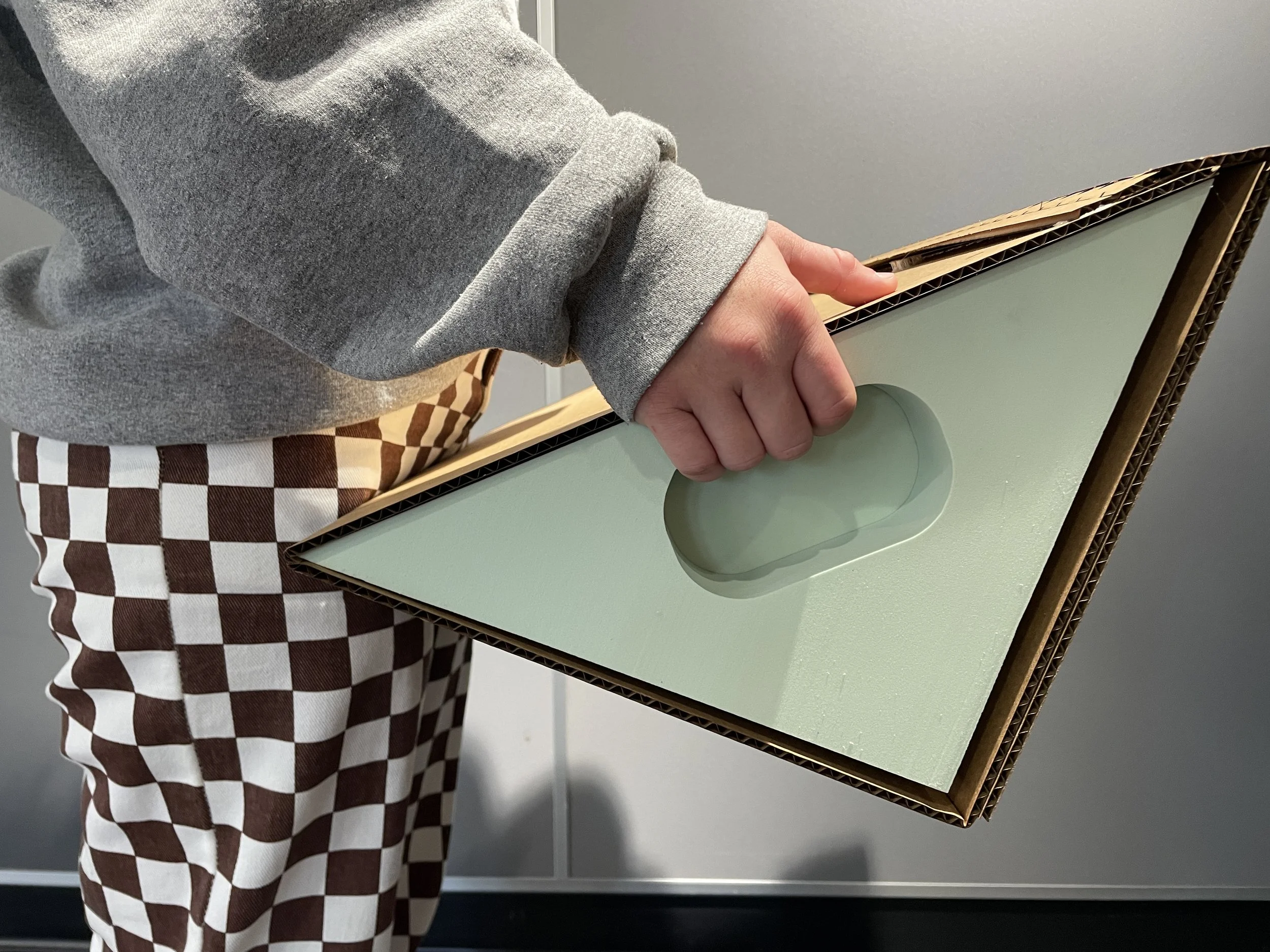

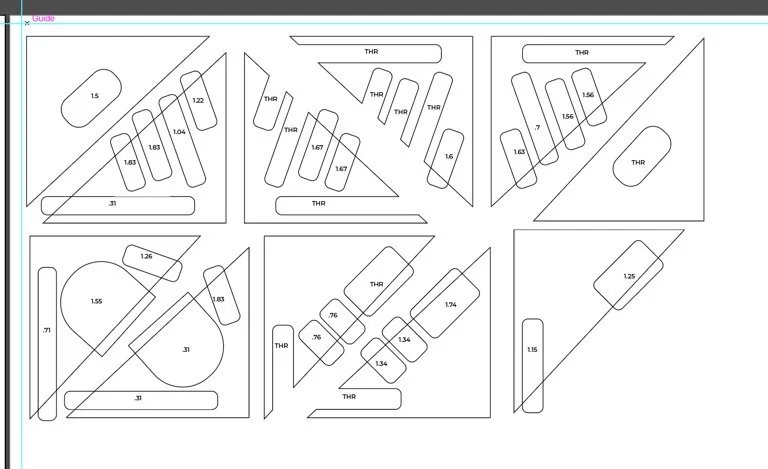

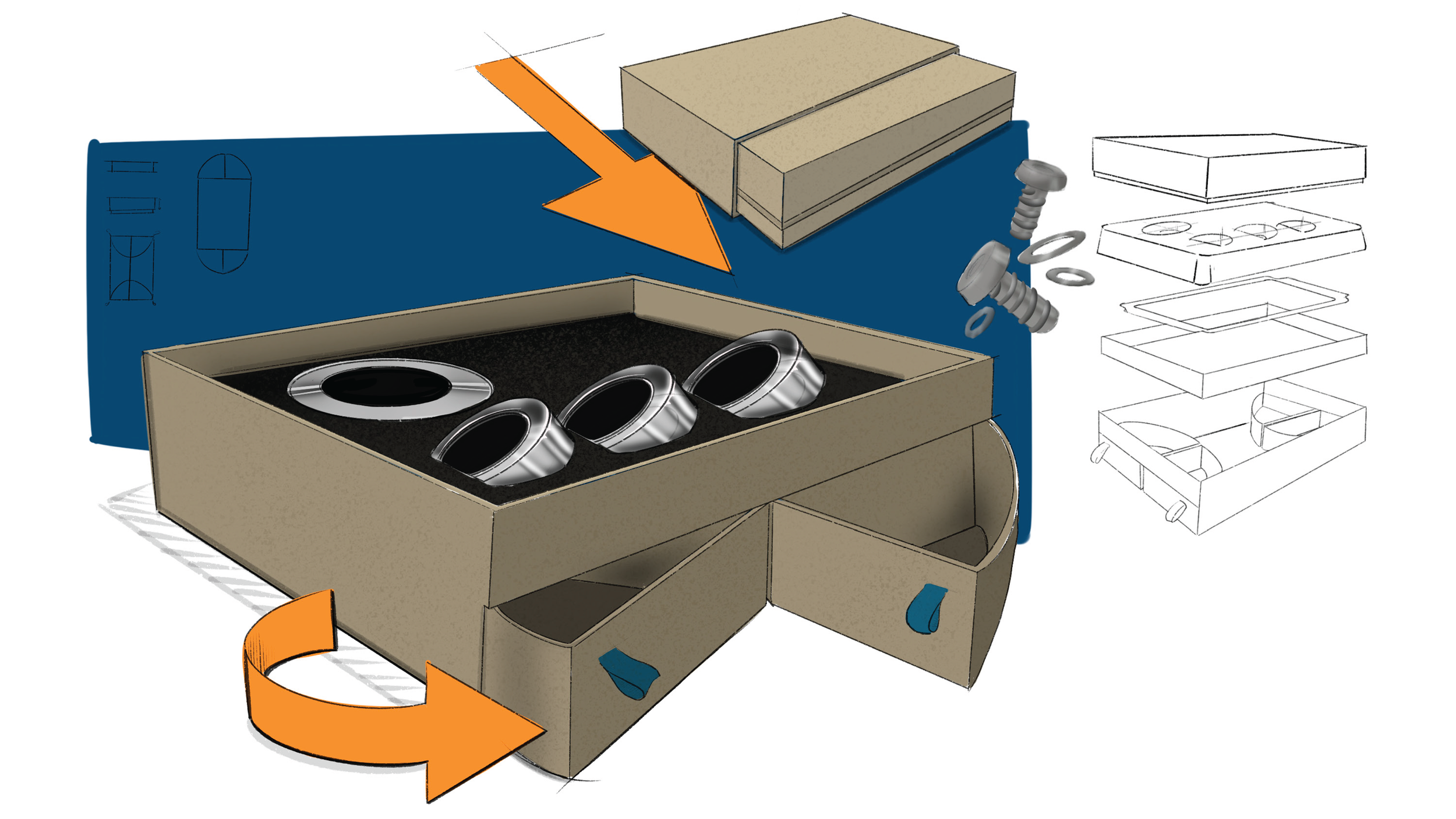

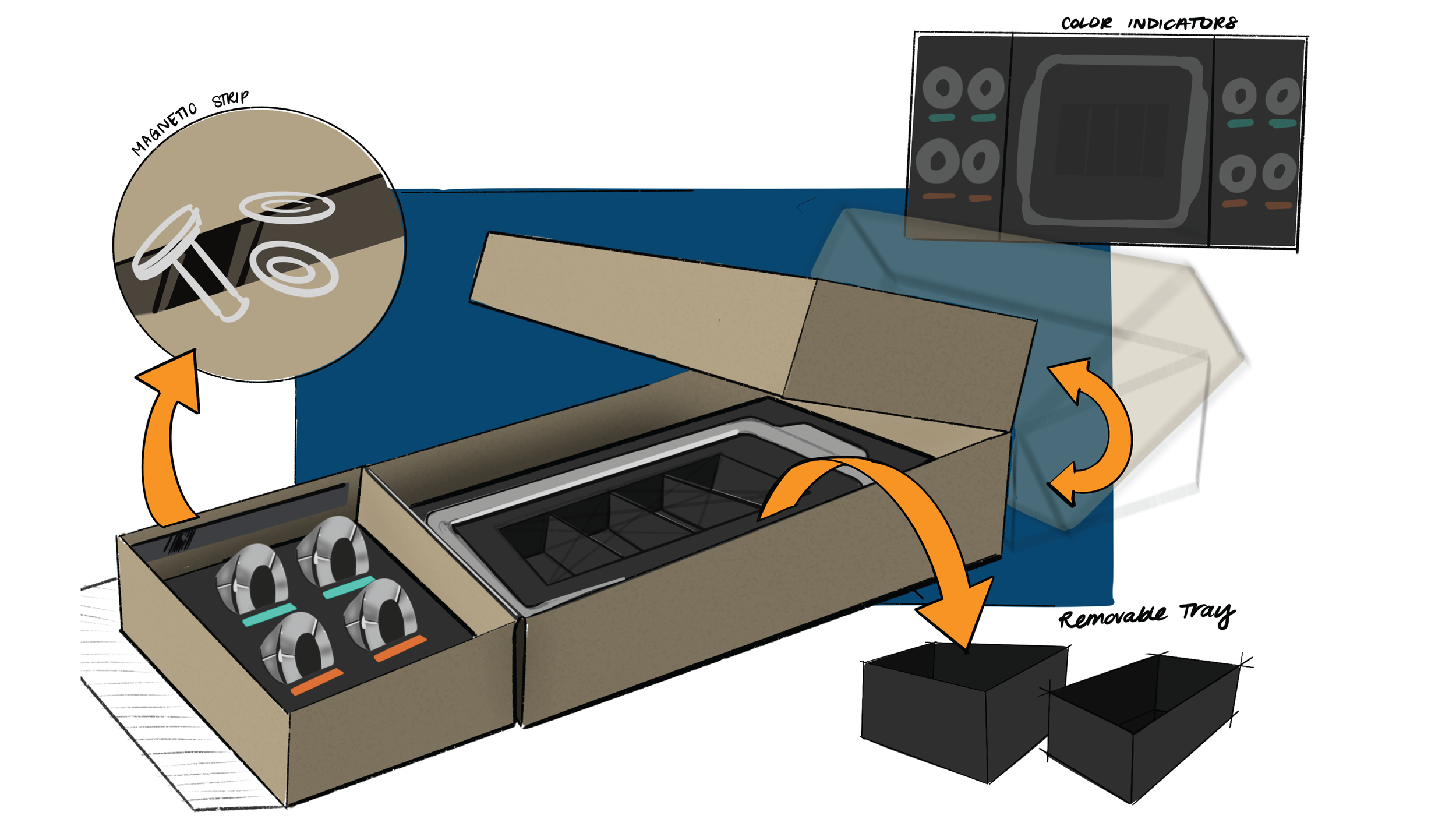

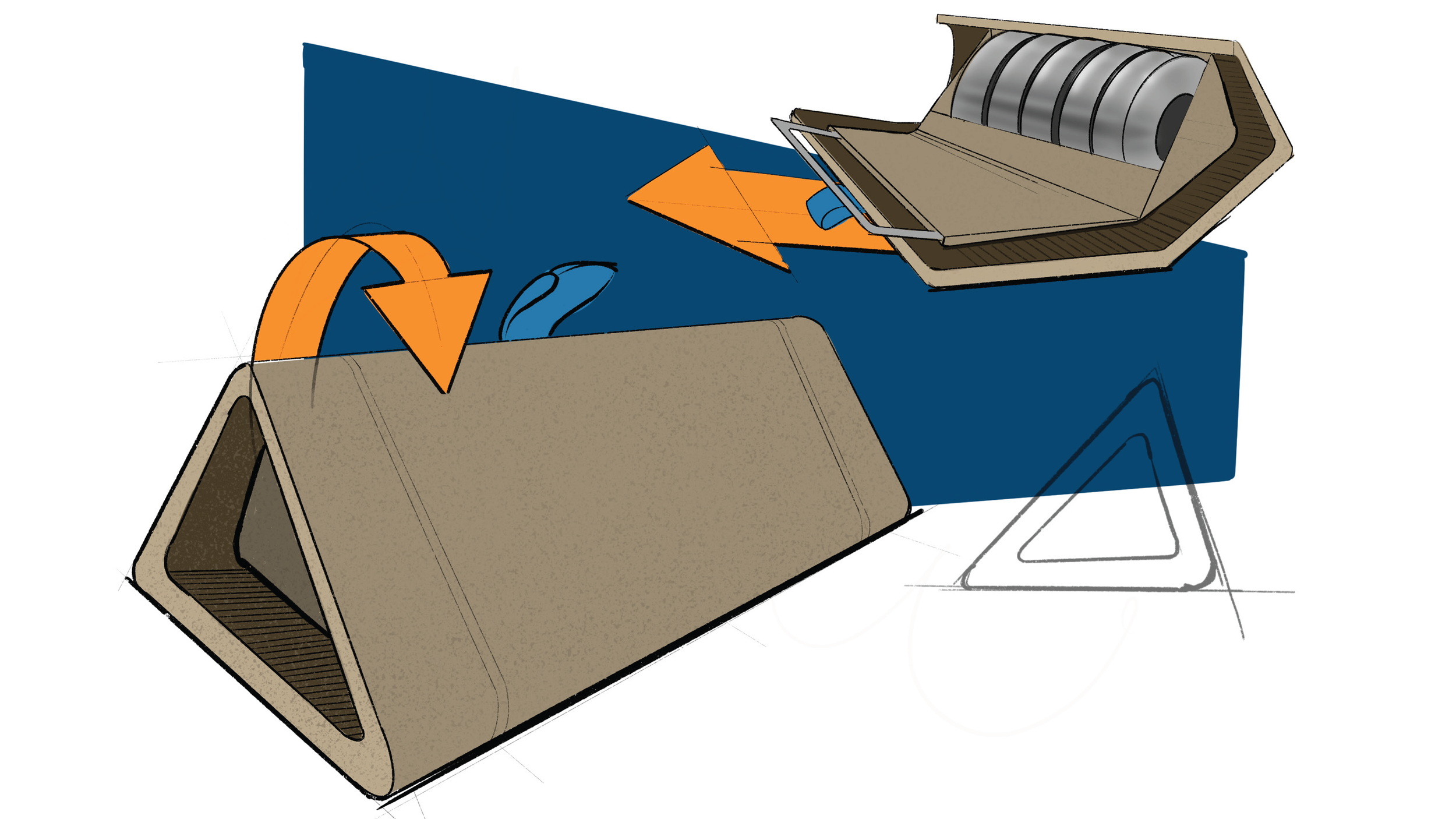

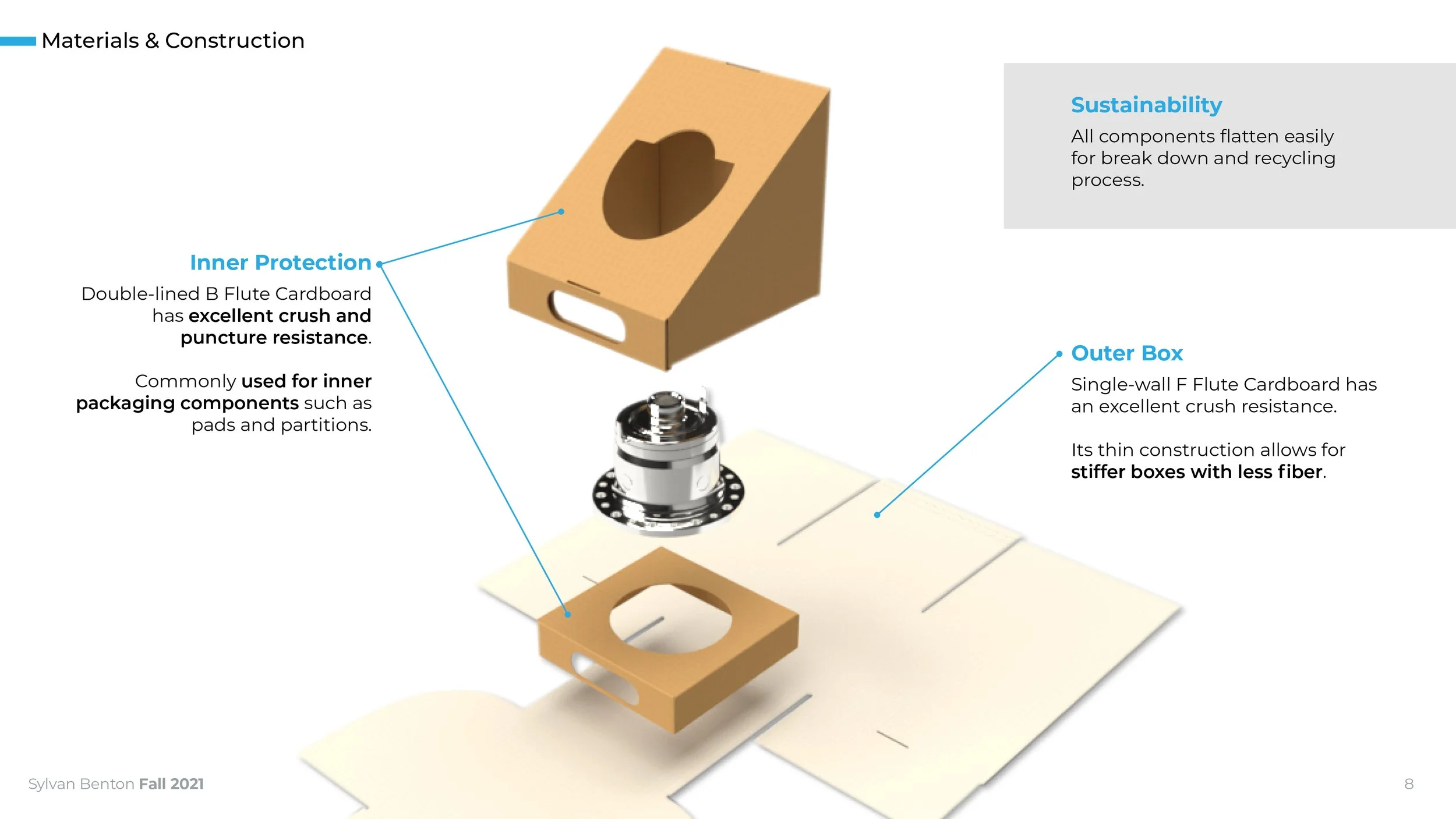

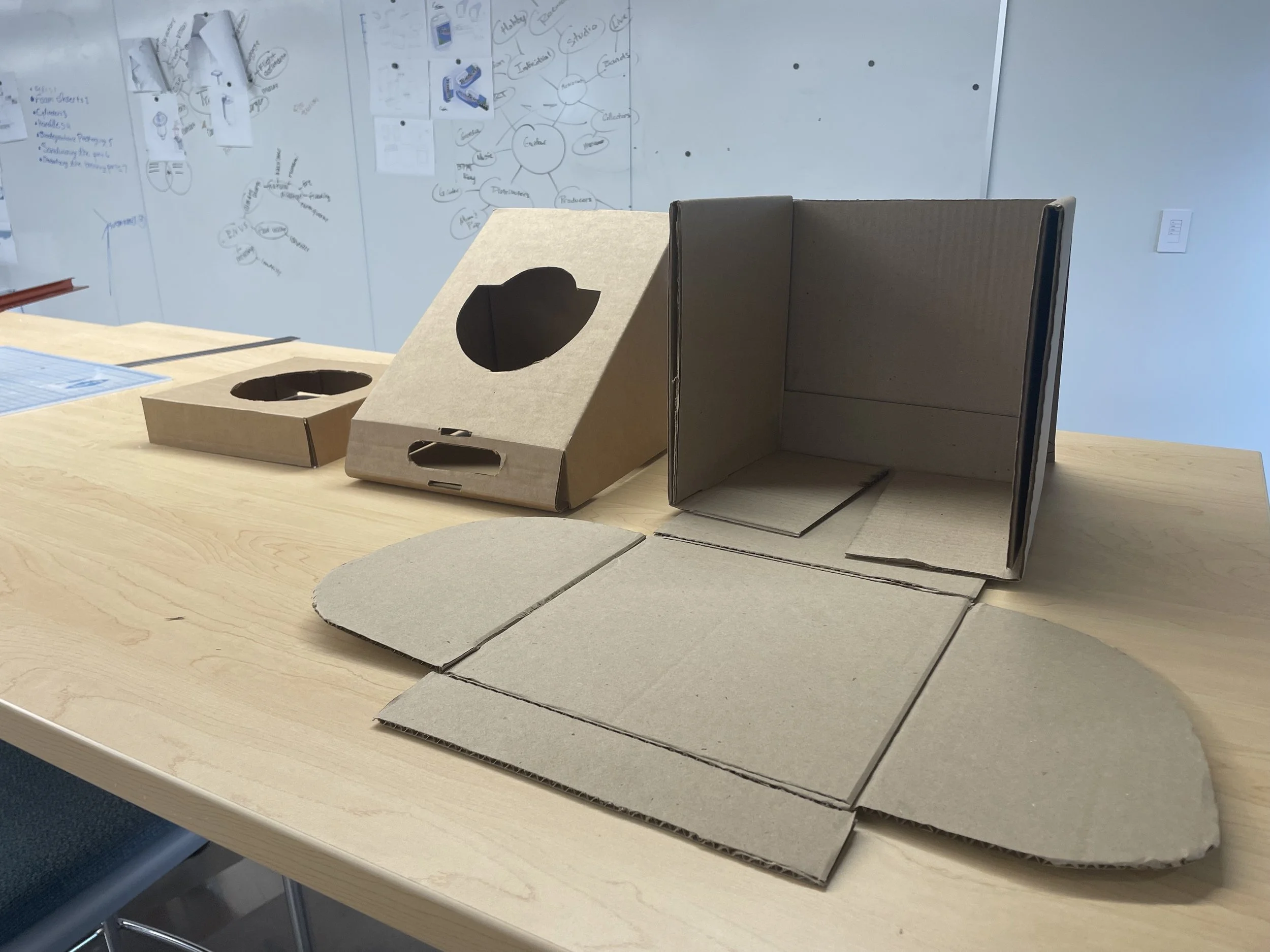

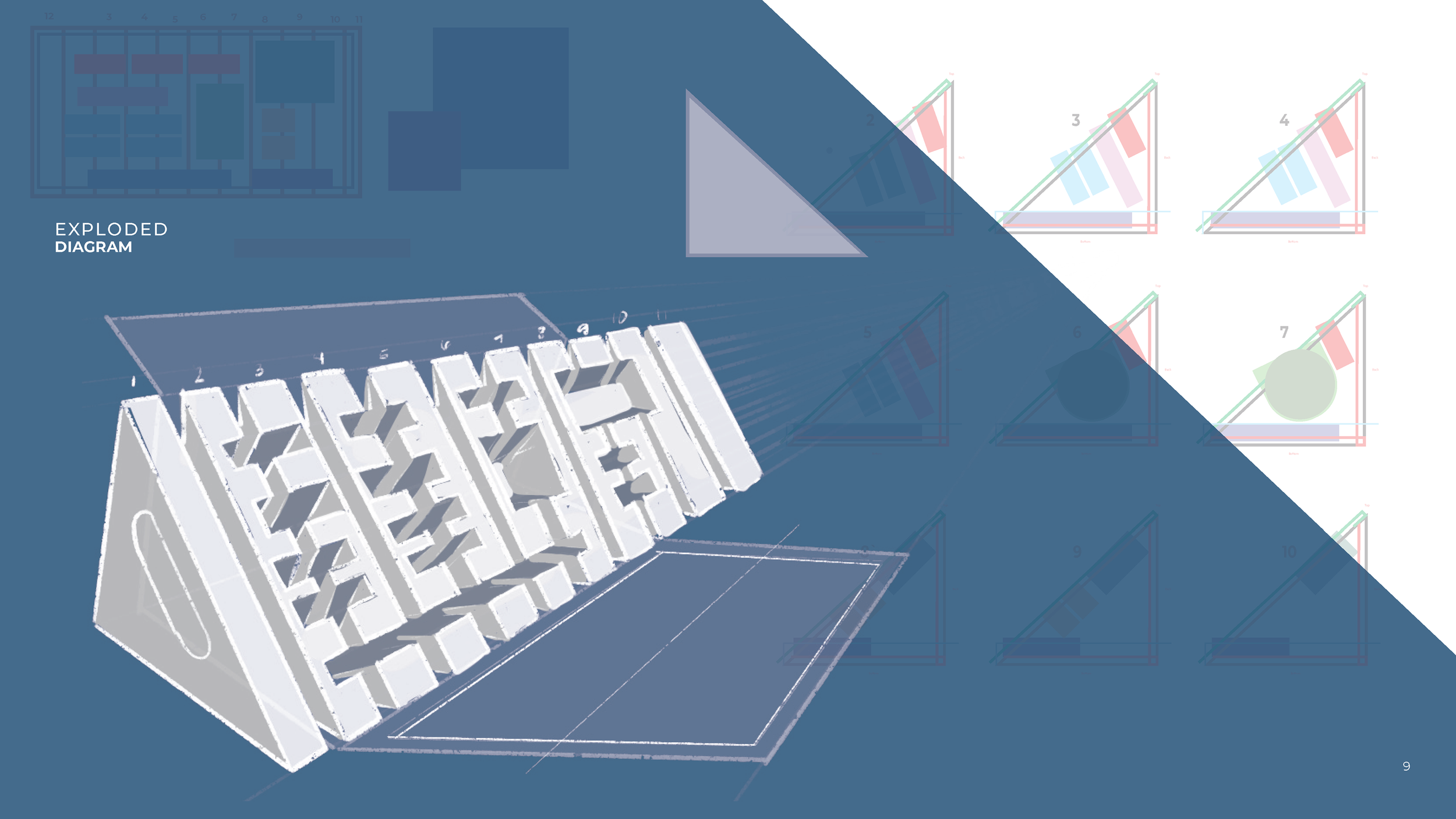

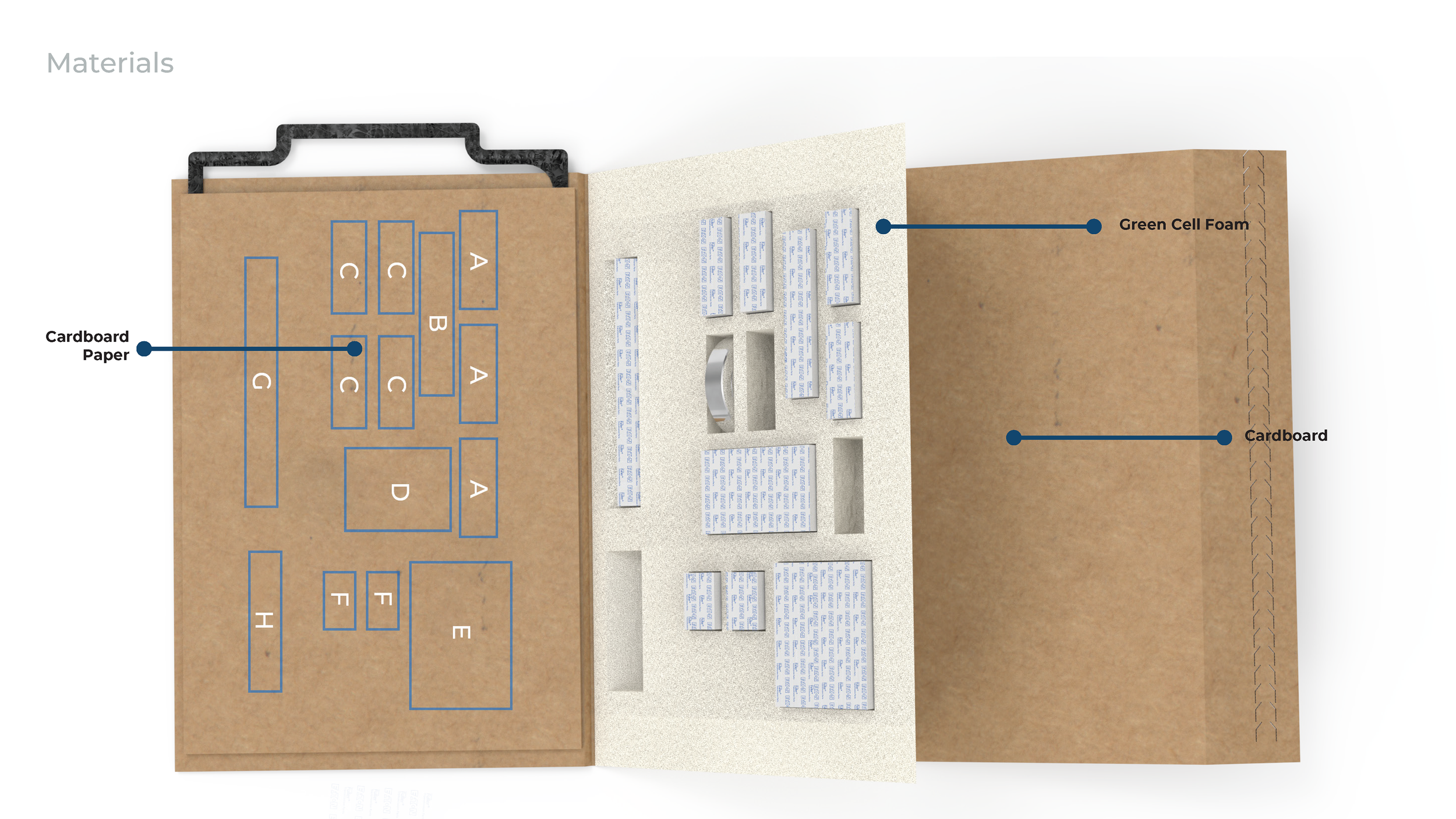

A triangular packaging design that organizes components in a foam insert, displaying parts at an ergonomic angle that allows mechanics to view all components at once. The solution improved assembly line efficiency through intuitive packing design, optimized shipping density to reduce costs, and transformed the end-user experience through thoughtful organization and presentation.

My Role

Designer

Methods

Stakeholder interviews and observations, Ergonomic analysis, Rapid prototyping, and 3D modeling

Tools

Fusion 360, Laser Cutter

Year

Fall 2021

Key Learnings

Designing across multiple stakeholders

This project taught me how to balance competing needs across different user groups. What's efficient for packaging employees isn't always optimal for shipping, and what's best for shipping might compromise the end-user experience. I learned to map these tensions explicitly and find creative solutions that addressed core needs across groups without compromising any single stakeholder's experience.

Efficiency through organization

I discovered that thoughtful organization serves multiple purposes simultaneously. By creating a specific place for each component, I simplified packing for employees, maintained order during shipping, and created an intuitive inventory system for mechanics.

Form following multiple functions

The triangular form emerged not from aesthetic preferences but from functional requirements—ergonomic viewing angle, shipping optimization, and structural integrity. This project reinforced that the most elegant solutions often arise when form directly addresses multiple functional needs rather than being determined in isolation.

Business impact of design decisions

This project opened my eyes to how seemingly small design decisions can have significant business impacts. By optimizing for shipping density, reducing assembly time, and improving the end-user experience, this packaging redesign created potential cost savings while enhancing the product experience—a powerful reminder that good design creates business value.